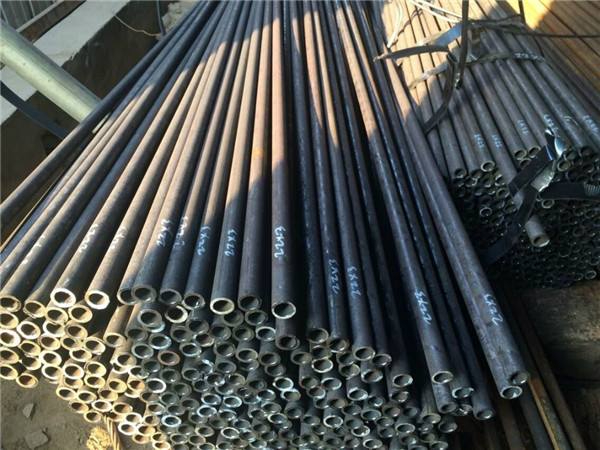

精軋鋼管生產商生產的精軋鋼管的用途廣泛:精密(mì)液壓無縫鋼管主要應用於液壓係統和(hé)油路管道。主要應用於液壓係統用配管(guǎn)、注塑機、液(yè)壓機、製鞋機械、液壓設備、高壓油管、卡套(鋼管)接頭連(lián)接、橡膠(jiāo)機械、鍛壓機械(xiè)、壓鑄機、工程機械、環衛車用、汽車行業、造船工業、金屬加工、軍工、柴油機、內燃機、空壓機、建築機械、船舶設備(bèi)(ccs認證)、冶金設備、農(nóng)林(lín)機械等(děng).德標鋼管有限公司生產出的精軋鋼管是精密冷拔後的無縫管(guǎn)通過無氧回火處理消除表麵和內(nèi)部應力後再經過磷化防鏽處理製成。

Precision hydraulic seamless steel pipes are mainly used in hydraulic systems and oil pipelines. Mainly used in hydraulic system piping, injection moulding machine, hydraulic press, shoemaking machinery, hydraulic equipment, high pressure oil pipe, clamp sleeve (steel pipe) joint connection, rubber machinery, forging and pressing machinery, die casting machine, engineering machinery, environmental sanitation vehicle, automobiles industry, shipbuilding industry, metal processing, military industry, diesel engine, internal combustion engine, air compressor, etc. Construction machinery, Shipbuilding Equipment (ccs certification), metallurgical equipment, agricultural and forestry machinery, etc. The finished steel pipe produced by Debiao Steel Pipe Co., Ltd. is a seamless pipe after precision cold drawing, which is made by phosphating and rust-proof treatment after eliminating surface and internal stress through oxygen-free tempering treatment. 精軋鋼管生產(chǎn)商生產的產品尺寸精度高,延展性好,容易加工彎成各種需要的形狀而管子(zǐ)截麵不會縮小或變扁;管子表麵精度高、經無氧回火處理後表麵硬度適中易於(yú)卡套連接,內孔和表麵經磷化防鏽處理後無(wú)需酸洗除鏽可直接安裝,精密液壓無縫鋼(gāng)管獨特的優越性,在液壓行業得到廣泛推廣應用,精(jīng)密(mì)液壓鋼管使用方便,節約時間和成本,提高工作(zuò)效(xiào)率。

The products manufactured by the finishing steel pipe manufacturer have high dimensional accuracy, good ductility, easy processing and bending into various required shapes without shrinking or flattening the cross section of the tube, high surface accuracy, moderate surface hardness after anaerobic tempering treatment, easy jacket connection, and no acid cleaning and rust removal are needed for inner hole and surface after phosphating and rust prevention treatment. Installation, precise hydraulic seamless steel pipe has unique advantages, which has been widely applied in the hydraulic industry. Precision hydraulic steel pipe is easy to use, saves time and cost, and improves work efficiency.

精軋鋼管生產(chǎn)商生產的熱軋精軋鋼管(guǎn)用連鑄圓(yuán)管坯板坯或初軋板坯作(zuò)原料,經步進式加熱爐加熱,高壓(yā)水除鱗後進入粗軋機(jī),粗軋料經(jīng)切頭、尾、再進入精軋機(jī),實施計算機控製軋製,終軋後(hòu)即經過層流冷卻(què)和(hé)卷取機卷取、成(chéng)為直發卷。直發卷的(de)頭、尾往往呈舌狀及(jí)魚尾狀,厚度、寬度(dù)精度較差,邊部常存在浪形、折(shé)邊、塔形等缺陷。

Hot-rolled finishing steel pipes manufactured by finishing steel pipe manufacturers use continuous casting round tube slab or blooming slab as raw material, heated by walking-beam heating furnace, descaling by high-pressure water, and then entering rough rolling mill. The rough rolling material is cut, tailed and re-entered into finishing mill. Computer controlled rolling is implemented. After finishing rolling, it is coiled and formed by laminar cooling and coiler. For straight hair rolls. The head and tail of straight hair curls are usually tongue-like and fish-tail-like, and the accuracy of thickness and width is poor. The edges of straight hair curls are often corrugated, folded and tower-shaped.