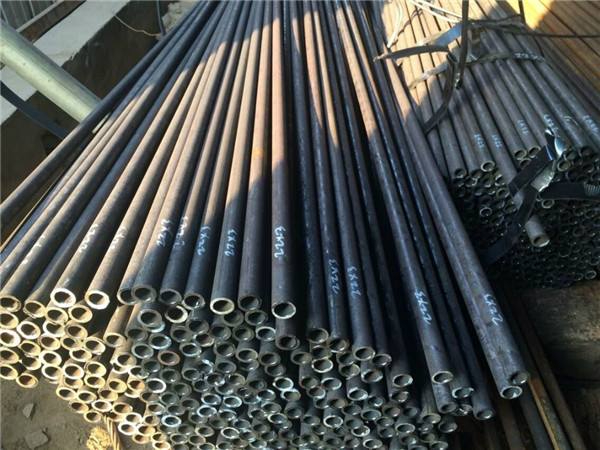

精軋鋼管就(jiù)是精軋(zhá)無縫鋼管,冷拔無縫(féng)鋼管的主(zhǔ)要生產流程(chéng) 管坯及坯加熱、管坯的穿(chuān)孔、鋼管(guǎn)的延伸、精軋鋼管的(de)軋製、鋼管定徑與減徑、鋼管的冷卻和精整 或者可以說是鋼胚的加熱、穿孔、熱紮(zhā)、酸洗、冷拔、碳(tàn)燒、切頭、噴標、包裝、成品(pǐn)冷拉鋼管是在常溫條件下,以超過原(yuán)來(lái)鋼(gāng)筋屈服點強度的拉應力,強行拉伸鋼筋,使鋼(gāng)筋產生塑性變形(xíng)以達到提高鋼筋屈服點強(qiáng)度和節(jiē)約鋼材為目的。

Fine-rolled steel pipe is the finely-rolled seamless steel pipe. The main production process of seamless steel pipe is heating billet and billet, perforation of billet, extension of steel pipe, rolling of steel pipe, sizing and reducing of steel pipe, cooling and finishing of steel pipe or heating of steel embryo, piercing, hot binding, pickling, cold drawing, carbon burning, cutting head, spraying mark, package. Cold-drawn steel pipes are loaded and finished at room temperature, in order to increase the yield point strength of steel bars and save steel, the tensile stress exceeding the original yield point strength of steel bars is forced to stretch steel bars so as to produce plastic deformation of steel bars. 精軋鋼管(guǎn)的概念:以節約鋼材、提高鋼筋屈服強度為目的,以超過屈服強度而又小於極(jí)限強度的拉(lā)應力拉伸鋼筋,使其產生塑性變形的做法叫(jiào)鋼筋冷(lěng)拉。產品廣泛應用於:機械設備:木工(gōng)機(jī)械、陶瓷(cí)機械、造紙機械(xiè)、玻璃(lí)機械、食品機械、建築機械、塑料機械、紡織機械、千(qiān)斤頂、液壓機等(děng)。

The concept of finish rolling steel pipe: for the purpose of saving steel and improving the yield strength of steel bars, the method of cold drawing of steel bars is to produce plastic deformation by stretching steel bars under tension stress which exceed the yield strength and are less than the ultimate strength. Products are widely used in: machinery and equipment: woodworking machinery, ceramic machinery, paper machinery, glass machinery, food machinery, construction machinery, plastic machinery, textile machinery, jacks, hydraulic presses and so on.

磁力(lì)機械(xiè)油封的工作原理:磁力機械油(yóu)封由靜環和動環兩部分組成,靜環(huán)材料(liào)為高強度磁性不鏽鋼合金,安裝於密封座內;動環安(ān)裝於轉動軸上(shàng),其上鑲嵌有磁性材料,並環(huán)嵌由碳和(hé)石墨製作的耐磨且潤滑良好的密封(fēng)材料。當精軋鋼管(guǎn)的磁力油封動(dòng)靜環安裝完畢貼合後,無論轉軸轉動與否,動環上磁性材料的磁力始(shǐ)終(zhōng)保證動靜環之間是緊密貼合(hé)的,從(cóng)而(ér)達到密封效果。磁力油封的這種工作原理,使其真正實現了(le)高、低轉速和靜(jìng)止時的(de)零泄露(lù)。此(cǐ)外(wài),這種油封還有使用壽(shòu)命(mìng)長,結構簡單,維護工作量(liàng)小(xiǎo)等優點。

The working principle of the magnetic mechanical oil seal: the magnetic mechanical oil seal consists of a static ring and a moving ring. The material of the static ring is a high strength magnetic stainless steel alloy, which is installed in the seal seat. The moving ring is installed on the rotating shaft, which is inlaid with magnetic material, and the ring is inlaid with wear-resistant and lubricating sealing material made of carbon and graphite. When the magnetic oil seal dynamic and static rings of the finishing rolling steel pipe are installed and fitted, the magnetic force of the magnetic material on the dynamic rings always ensures that the dynamic and static rings are closely fitted, regardless of whether the rotating shaft rotates or not, so as to achieve the sealing effect. The working principle of magnetic oil seal makes it realize zero leakage at high, low speed and static state. In addition, the oil seal has the advantages of long service life, simple structure and small maintenance workload.