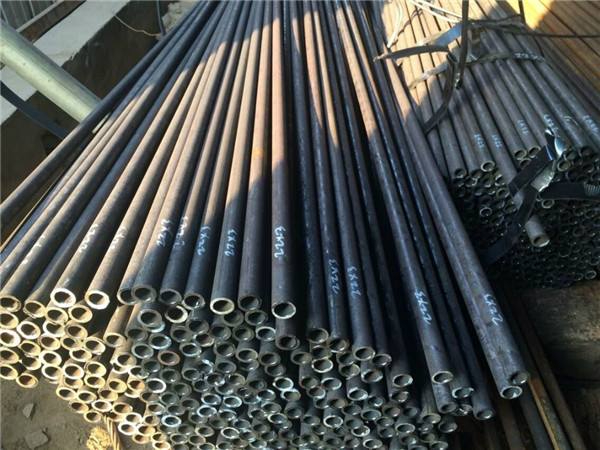

冷拔無縫鋼管的腐蝕性的問題已經是一個比較嚴重的(de)問題了,很多的廠家(jiā)也是因為腐蝕成本也是在不斷地進行升高,每年光腐蝕導致的直接的經濟(jì)損失就達到了數億元,是一筆非常龐大的開支。所(suǒ)以說應該對於腐蝕性應該及時進行處理,挽回經濟損失。冷拔無縫鋼管為什麽會腐蝕呢?這些因素或者是與腐蝕有著(zhe)直接的關係。具體的話我們直接進行看一(yī)下相關的介紹:

Corrosivity of cold-drawn seamless steel tubes has become a serious problem. Many manufacturers are also increasing the cost of corrosion. The direct economic loss caused by light corrosion every year reaches hundreds of millions of yuan, which is a huge expenditure. Therefore, corrosiveness should be dealt with in time to recover economic losses. Why are cold-drawn seamless steel tubes corroded? These factors are directly related to corrosion. Specifically, let's take a look at the relevant introduction directly. 1、首先是外界條件的影響。主要是先(xiān)看管道(dào)周圍的介質特性、溫度,以及管(guǎn)道(dào)周圍所處的介質是不是具有腐蝕性。因為介質腐蝕性的高低與土(tǔ)壤所含的各項微(wēi)生物有著(zhe)密切的關係(xì)。並且如(rú)果是長輸管道的話,土壤環境性質更加複雜。除此之外,管道所處環境的溫度也會影響冷拔無縫鋼管的腐蝕,如果溫度較高,腐蝕的速度也會加快,而溫度低則(zé)腐蝕速度(dù)減慢。

1. The first is the influence of external conditions. Mainly depends on the characteristics of the medium around the pipeline, temperature, and whether the medium around the pipeline is corrosive. Because the corrosiveness of the medium is closely related to the microorganisms in the soil. And if it is a long-distance pipeline, the soil environment is more complex. In addition, the temperature of pipeline environment will also affect the corrosion of cold-drawn seamless steel pipe. If the temperature is higher, the corrosion speed will be accelerated, while the corrosion speed will be slowed down when the temperature is low.

Cold-drawn seamless steel tubes. jpg

2、就是防腐失效。管道在架(jià)設的時候要做好防腐工作(zuò)或者直接使用防腐冷拔無縫鋼管,管道遭到腐蝕的原因是因為管道的防腐層遭到了破壞。防腐層和管道表麵一旦脫離,就會自然造成防(fáng)腐失效。

2. Corrosion protection is invalid. When pipeline is erected, it is necessary to do a good job of anti-corrosion or use anti-corrosion cold-drawn seamless steel pipe directly. The reason why pipeline is corroded is that the anti-corrosion layer of pipeline is damaged. Once the anticorrosive coating and pipeline surface are separated, it will naturally cause anticorrosive failure.

以上就(jiù)是冷拔無縫鋼管腐蝕性的(de)主要的原因,大家可以避免這些原因,找到解決防止腐蝕性的辦法,這樣的話才能夠獲得比較好的效果!

Above is the main reason for the corrosiveness of cold-drawn seamless steel tubes. We can avoid these reasons and find solutions to prevent corrosiveness, so that we can get better results!