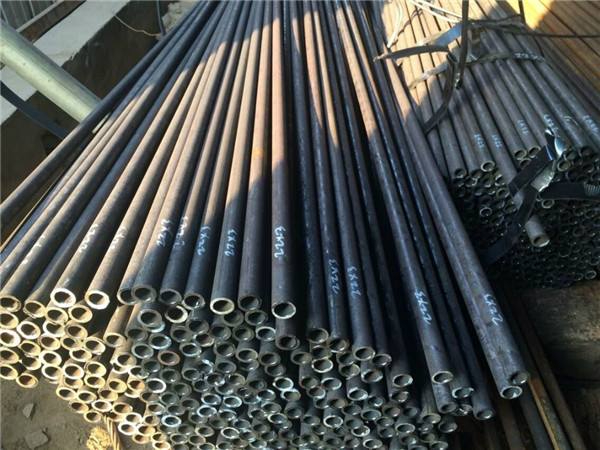

在焊管(guǎn)生產(chǎn)的過程中,退火(huǒ)溫度(dù)起(qǐ)著中藥作用,退火溫度是否達到規定溫度。焊管熱處理一般是采取(qǔ)固溶熱處理(lǐ),也就是人們(men)平常所謂的“退火”,溫度範圍為1040~1120℃(日本標準(zhǔn))。你也可以通過退火爐觀察孔觀察,退火區的焊接鋼管應為白熾狀態,但沒出現軟化下垂。退火溫(wēn)度為引物和模板結合時候的溫度參數,當50%的引物和互補序列表現為雙鏈DNA分(fèn)子時的溫度?它是影響PCR特異性的較(jiào)重要(yào)因素。在理想狀態下,退火溫度足夠(gòu)低,以保證引物同目的序列(liè)有效退火, 同時還要足夠高,以減少非特異性結合。合理的退火溫度從55℃到70℃。退火溫度一般設定比引物的 Tm低5℃。

Annealing temperature is the temperature parameter when primers and templates are combined. When 50% of primers and complementary sequences are double-stranded DNA molecules, temperature is an important factor affecting the specificity of PCR. Ideally, the annealing temperature is low enough to ensure the effective annealing of primers with the same target sequence, and high enough to reduce non-specific binding. Reasonable annealing temperature ranges from 55 to 70 C. The annealing temperature is generally set to be 5 C lower than the Tm of the primer. In the production of welded steel pipe, annealing temperature plays a role of traditional Chinese medicine, whether the annealing temperature reaches the prescribed temperature or not. The heat treatment of welded steel pipes is usually solid solution heat treatment, which is commonly called "annealing", and the temperature range is 1040 ~ 1120 ("Japan Standard"). You can also observe the holes in the annealing furnace. The welded steel pipe in the annealing zone should be incandescent, but there is no softening sag. 其次是退火氣氛(fēn)。一般都(dōu)是采用純氫作為退(tuì)火氣氛(fēn),氣氛純度最好是99.99%以上(shàng),如果氣(qì)氛中另一部分是惰性(xìng)氣體的話,純度也可以低(dī)一點,但是絕對不能含有過多氧(yǎng)氣、水汽。光亮退火爐應是封閉的(de),與外界空(kōng)氣隔絕;采用氫氣作保(bǎo)護氣的,隻有一(yī)個排氣口是通的(用來點燃排出的氫氣)。檢查的方法可以用肥皂水抹在退火(huǒ)爐各個接(jiē)頭縫隙處,看是否(fǒu)跑氣;其中最容易跑氣的地方是退火(huǒ)爐進管子的地(dì)方和出管子的地方,這個地方的密(mì)封圈特別容易磨損,要經常檢查經常換(huàn)。

Next is annealing atmosphere. Usually pure hydrogen is used as annealing atmosphere. The purity of the atmosphere is better than 99.99%. If the other part of the atmosphere is inert gas, the purity can be lower, but absolutely can not contain too much oxygen and water vapor. Bright annealing furnace should be closed, isolated from the outside air; using hydrogen as protective gas, only one exhaust port is open (used to ignite the exhaust hydrogen). Soap water can be used to smear the cracks in each joint of the annealing furnace to see if it runs out. The most easily runs out is the place where the annealing furnace enters and leaves the tube. The sealing rings in this place are particularly easy to wear and tear, so it is necessary to check and replace them frequently.

在金屬加(jiā)工領域,退火溫度是指退火時金(jīn)屬應加熱達到(dào)的溫度。據有(yǒu)關文獻介(jiè)紹,不同金屬材料的退火溫度為:鉑,900―1000℃;銅,650℃;黃銅,600―650℃;鎳銀,650―680℃;鋁(lǚ),283―350℃等。

In the field of metal processing, annealing temperature refers to the temperature at which the metal should be heated during annealing. According to the relevant literature, the annealing temperatures of different metal materials are: platinum, 900-1000 degrees C; copper, 650 degrees C; brass, 600-650 degrees C; nickel and silver, 650-680 degrees C; aluminium, 283-350 degrees C, etc.

最後是(shì)保護氣壓力。為了防(fáng)止出現微漏,爐(lú)內保護氣應保持一定的正壓,如果是氫氣保護氣,一般要求20kBar以上。一方麵檢查爐體材料是否幹(gàn)燥,初次裝爐,爐體材料必(bì)須要烘幹;二是進爐的焊接鋼管是否殘留過多水(shuǐ)漬,特別管(guǎn)子上麵如果有孔的話(huà),千(qiān)萬別漏水(shuǐ)進去了,要不然就把爐子(zǐ)氣(qì)氛全(quán)破(pò)壞了。

Finally, the protective pressure. In order to prevent slight leakage, the protective gas in the furnace should maintain a certain positive pressure. If it is hydrogen protective gas, the general requirement is more than 20 kBar. On the one hand, check whether the material of the furnace body is dry or not, and the material of the furnace body must be dried for the first time. On the other hand, whether there are excessive water stains left on the welded steel pipe entering the furnace, especially if there are holes in the pipe, don't let water leak in, or the atmosphere of the furnace will be destroyed completely.