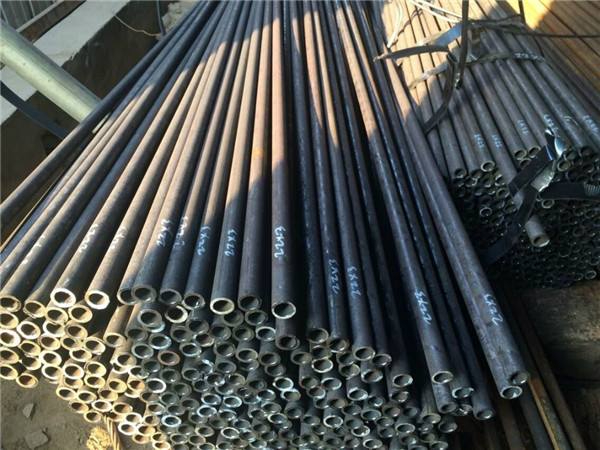

首先焊管成型過程中,鋼板變形(xíng)均勻,殘餘應力小,表麵(miàn)不產生劃傷。加(jiā)工的焊管在(zài)直徑和(hé)壁厚的尺寸規格範圍上有更大的靈活性,尤其在生產高鋼級厚壁管,特別是(shì)中小口徑厚壁管方麵具有其他工藝無(wú)法比擬的優勢,可滿足用戶在焊管規(guī)格方麵更多的要求;采用(yòng)先預焊(hàn)後內外焊(精焊)的工藝,可在最(zuì)佳位(wèi)置實(shí)現焊接,不易出現錯邊、焊偏和未(wèi)焊透等(děng)缺陷(xiàn)。

Firstly, during the forming process of welded pipe, the steel plate has uniform deformation, small residual stress and no scratch on the surface. Processed welded pipes have greater flexibility in the size and specification range of diameter and wall thickness, especially in the production of high-grade thick-walled steel pipes, especially medium and small-sized thick-walled pipes, which have incomparable advantages compared with other processes, and can meet more requirements of users in the specification of welded pipes. The process of pre-welding before internal and external welding (fine welding) can be used to achieve welding in the best position, and it is not easy to appear staggered edges. Defects such as welding deviation and impermeability. 如果進(jìn)行整體機械擴徑,可有效地提高焊管的(de)尺寸精度,並改善焊管(guǎn)內應力的分布狀態,從而避免由於應力腐蝕造成的破壞,同時有利於現場的焊接施工;對焊管進行9項100%的質量(liàng)檢查,使焊管生產的全過程均在有效(xiào)的檢測、監(jiān)控之下,有效地保證了產品質量。

If the overall mechanical diameter enlargement is carried out, the dimensional accuracy of welded pipe can be effectively improved, and the stress distribution in welded pipe can be improved, so as to avoid the damage caused by stress corrosion, and at the same time, it is conducive to the field welding construction; 9 100% quality inspections are carried out on welded pipe, so that the whole process of production of welded pipe is effectively inspected and monitored, and the product quality is effectively guaranteed.

焊管工藝流程(chéng):原材料開卷――平整――端部剪切及焊接――活套――成(chéng)形――焊接――內外焊珠(zhū)去除――預校正――感應(yīng)熱處理――定徑及校直――渦流檢測――切(qiē)斷――水壓檢查――酸洗――最終檢查(嚴格把關)――包裝――出貨。

Welded pipe process: raw material uncoiling - leveling - end shearing and welding - looper - forming - Welding - internal and external bead removal - pre-correction - induction heat treatment - sizing and straightening - eddy current testing - cutting - water pressure inspection - acid washing - final inspection (strict control) - Packaging - delivery.

焊管廣泛應(yīng)用於(yú)自(zì)來水工程、石(shí)化工業、化(huà)學工業、電力工業、農業灌溉、城市建設,是我國開發的二十個重點產品(pǐn)之一。

Welded pipe is widely used in tap water engineering, petrochemical industry, chemical industry, electric power industry, agricultural irrigation, urban construction, and is one of the 20 key products developed in China.