nd鋼管在使(shǐ)用前需要經過嚴格的檢查,隻有達(dá)到(dào)標準的產品才能使用,在檢查nd鋼管時會根據nd鋼管的表麵亮度,製作的材質及nd鋼管產品(pǐn)的工藝手法來判斷。現在小編要為大家介紹的就是nd鋼管檢查的三種方法。一次漫不經心,一次不大的失(shī)誤,會導致無法預料的後果,甚至是要付出血的代價。正所謂安全第一,預防為主。為nd鋼(gāng)管生產線安全買份保險,這保險便是職工的安全意識,隻有提高職工的安全意識才能達(dá)到人人抓安全、人人重安全,才能將各類nd鋼管生產安全隱患消除在萌芽狀態。

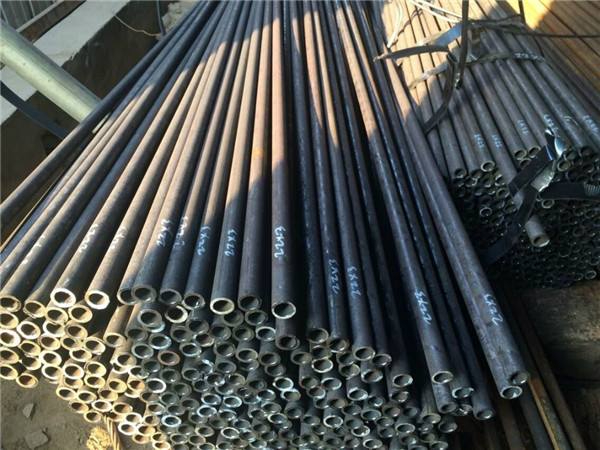

ND steel pipe needs to undergo rigorous inspection before use, only the products that meet the standard can be used. When inspecting ND steel pipe, it will be judged according to the surface brightness of ND steel pipe, the material made and the technological methods of ND steel pipe products. Now Xiaobian want to introduce three methods of ND steel pipe inspection. A carelessness, a minor mistake, will lead to unpredictable consequences, and even to pay the price of blood. The so-called safety first, prevention first. Buy an insurance for the safety of ND steel pipe production line. This insurance is the safety consciousness of workers. Only by improving the safety consciousness of workers can everyone grasp safety and put safety at the top of everyone's weight, and can all kinds of hidden dangers of ND steel pipe production be eliminated in the bud. 首先要看管的表(biǎo)麵。觀察亮度和表麵有無漏焊(hàn)和脫皮等表麵問題。好的nd鋼管(guǎn)表麵色澤(zé)光(guāng)亮,一般情況下不(bú)會生(shēng)鏽。

The first thing to look after is the surface. Observe the brightness and surface problems such as welding leakage and peeling. A good ND steel pipe has a bright surface and will not rust in general.

第二點就是看材質。化學成分是nd鋼(gāng)管的基(jī)礎(chǔ)。檢查化(huà)學成分是否達(dá)標是nd鋼管(guǎn)很重要的檢查方式。還有就(jiù)是檢(jiǎn)查是(shì)否精(jīng)煉爐(lú)的材料。

The second point is to look at the material. Chemical composition is the basis of ND steel pipe. Checking whether the chemical composition is up to the standard is an important inspection method for ND steel pipes. The other is to check whether the material of the refining furnace is available.

第三點就是要看(kàn)做工。圓管(guǎn)的圓度、方管的方度、表麵(miàn)的處理、nd鋼管兩端的處理、還有很重要的一點就是整隻鋼管的(de)平直度。

The third point is to look at the workmanship. Roundness of circular pipe, squareness of square pipe, surface treatment, treatment of both ends of ND steel pipe, and a very important point is the flatness of the whole steel pipe.

最後,好的(de)nd鋼管廠家擁有好的管理層、好的操作(zuò)工(gōng)、好的製(zhì)度、有一定的知名度和信(xìn)譽度,產出來的產品自然也能滿(mǎn)足客(kè)戶的高端要求。而一些小的或者不正規的鋼管廠家生產出來nd鋼管不僅在外(wài)觀上與好的nd鋼管有差距,其堅硬程度、韌性,也(yě)有很大(dà)的差距。

Finally, a good ND steel pipe manufacturer has good management, good operators, good system, a certain degree of popularity and credibility, and the products produced can naturally meet the high-end requirements of customers. And some small or irregular steel pipe manufacturers produced ND steel pipe not only in appearance and good ND steel pipe has a gap, its hardness, toughness, but also a big gap.

在工作中nd鋼管生產安(ān)全隱患錯綜複雜,變化無常,難以預(yù)料和掌控,稍有大意,便會(huì)釀(niàng)成(chéng)無(wú)法(fǎ)挽回的經濟損失甚至危機生命。隨著對工作熟練程度的加深(shēn),有些職工逐漸掉以輕心,自認(rèn)為(wéi)對(duì)操作流程熟練,從而忽略了基本的nd鋼管生產設備安全防範措施(shī)。

In the work, the hidden dangers of ND steel pipe production safety are complex, changeable, unpredictable and difficult to control. A little carelessness will lead to irreparable economic losses and even crises of life. With the deepening of working proficiency, some workers gradually take it lightly and think they are skilled in the operation process, thus ignoring the basic safety precautions for ND steel pipe production equipment.