螺旋焊管主要用途和直縫焊管的區別 .螺旋(xuán)焊管主要用(yòng)途:廣泛用(yòng)於房屋、橋梁、道路等土建(jiàn)工程建(jiàn)設(shè)。主要產地:螺旋管的生產廠家在我國主要(yào)分(fèn)布在(zài)華北和東北(běi),華北地區如首鋼、唐鋼、宣鋼、承鋼等(děng),東北地區如西林、北台、撫鋼等,這兩個地區約占螺紋(wén)鋼總產(chǎn)量50%以上。螺旋(xuán)焊管廣泛應用於(yú)天然氣(qì)、石油、化(huà)工、電力、熱力、給排水、蒸汽供熱、水電站用壓力鋼管、火(huǒ)力發電、水源等(děng)長距離輸送管(guǎn)線及打樁、疏浚、橋梁、鋼結構等工程領域(yù)。質量好壞螺旋焊管的橫筋細而(ér)低,經常出現充不滿的現象,原因是廠家為達到大的負公差,成品(pǐn)前幾道(dào)的壓下量偏大,鐵型偏小,孔型充不滿。

The main use of spiral welded pipe is different from that of straight welded pipe. The main use of spiral welded pipe is widely used in civil engineering construction such as houses, bridges and roads. Major Origins: Spiral pipe manufacturers are mainly distributed in North China and Northeast China. North China, such as Shougang, Tanggang, Xuangang, Chenggang, and Northeast China, such as Xilin, Beitai and Fugang, account for more than 50% of the total output of screw steel. Spiral welded pipe is widely used in natural gas, petroleum, chemical industry, electric power, thermal power, water supply and drainage, steam heating, penstock for hydropower station, thermal power, water and other long-distance transmission pipelines and piling, dredging, bridge, steel structure and other engineering fields. The quality of spiral welded pipe is thin and low, and the phenomenon of filling is often unsatisfactory. The reason is that in order to achieve a large negative tolerance, the manufacturer has a large reduction in the first several passes of the finished product, a small iron shape and a unsatisfactory filling of the pass. 隨(suí)著國民經濟的發展和(hé)人(rén)民生活水平的(de)提高,螺旋焊管已經成(chéng)為國內給管道係統發展的新趨勢.公司一貫信奉"質量第一,客戶至上,以誠會友,科(kē)技興企"。河北天元鋼管製造有限公司的理念是"合作、創(chuàng)新、求進、發展(zhǎn)"。 我本公司創辦以來,一直注重對(duì)產品的質量及對高難度產品的加(jiā)工管理、同時對外承接各種高難(nán)度加工生產焊管業務。實現用戶最完美的價值,是我們的奮鬥目標。

With the development of national economy and the improvement of people's living standards, spiral welded pipe has become a new trend in the development of domestic pipeline system. The company has always believed in "quality first, customer first, sincere friends, science and technology to thrive enterprises". The philosophy of Hebei Tianyuan Steel Tube Manufacturing Co., Ltd. is "cooperation, innovation, progress and development". Since the founding of our company, we have been focusing on the quality of products and processing management of high-difficulty products, while undertaking a variety of high-difficulty processing and production of welded pipe business. It is our goal to realize the most perfect value of users.

螺旋焊管與直縫焊管的區別

Difference between Spiral Welded Pipe and Longitudinal Welded Pipe

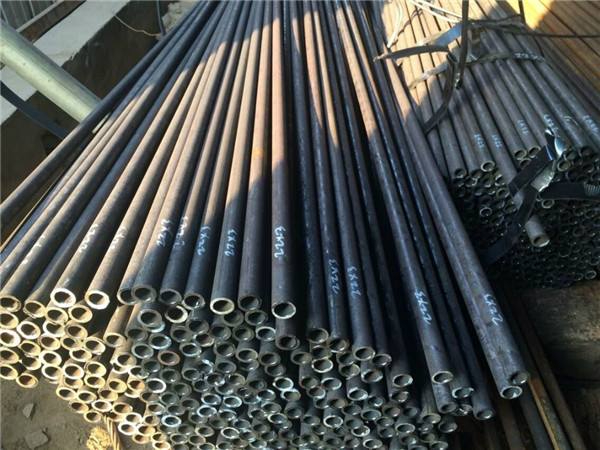

直縫埋弧焊管是用鋼板生產(chǎn)的(de),而螺旋焊管是用熱軋卷板(bǎn)生產的。熱軋帶鋼機組軋製(zhì)工藝具有一係列的優點,具有(yǒu)獲得(dé)生產優質管線鋼的冶金工藝能力。例如,在輸出台架上裝有水冷卻係統以加速冷(lěng)卻(què),這就允許使用(yòng)低合金成分來達到特殊的強(qiáng)度等級和低溫韌性,從而改進鋼材的可焊性。但(dàn)這一係統在(zài)鋼板(bǎn)生產廠基本沒有。卷板的合金含量(碳當量)往(wǎng)往低(dī)於相似(sì)等(děng)級的(de)鋼板,這也提高了螺旋焊管的可焊性。

Longitudinal submerged arc welded pipe is made of steel plate, while spiral welded pipe is made of hot rolled coil plate. The rolling process of hot-rolled strip mill has a series of advantages. It has the metallurgical ability to produce high quality pipeline steel. For example, a water cooling system is installed on the output bench to accelerate cooling, which allows the use of low alloy components to achieve special strength grades and low temperature toughness, thereby improving the weldability of steel. But this system is basically not available in steel plate factories. The alloy content (carbon equivalent) of coiled sheets is often lower than that of similar grade steel sheets, which also improves the weldability of spiral welded pipes.

更需要說(shuō)明的是,由於螺旋焊管的卷板軋製方向不是垂(chuí)直鋼(gāng)管軸線方向(其夾解取(qǔ)決於鋼管的螺旋角),而直縫鋼(gāng)管的鋼板軋製方向垂直於鋼管軸線方向,因而,螺旋焊管(guǎn)材料的抗裂性能優於直縫鋼管。

More importantly, because the rolling direction of spiral welded pipe coil is not perpendicular to the axis of the steel pipe (its clamping depends on the spiral angle of the steel pipe), while the rolling direction of the steel plate of the straight welded pipe is perpendicular to the axis of the steel pipe, the crack resistance of the spiral welded pipe material is better than that of the straight welded pipe.