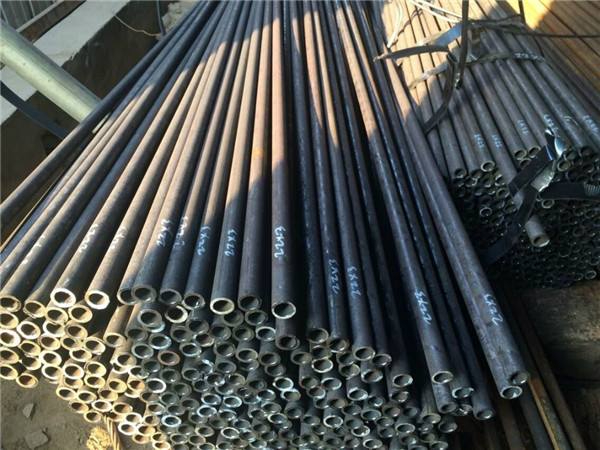

怎麽鑒別(bié)焊管材質是什麽(me)?土方法有目測,火花鑒別,還可以(yǐ)使用儀器放在焊管上就能(néng)檢測出來,或者上質監局去檢測。製造焊管的鋼(gāng)材一般分為型材,板材,管材和金屬製品四大類,為了方便進行使用和區分,又可以分為終軌輕(qīng)軌、大型型鋼、中(zhōng)型(xíng)型鋼、小型型鋼、鋼材冷彎(wān)型鋼,優質型鋼、線材、中厚鋼板、薄壁焊管、電工(gōng)用矽(guī)鋼片、帶鋼、無縫鋼管(guǎn)鋼材、焊接鋼管、金屬製品等品種。

How to identify the material of welded pipe? Soil method has visual inspection, spark identification, can also be detected by using instruments placed on welded pipe, or inspected by the quality supervision bureau. The steel products for manufacturing welded pipes are generally divided into four categories: profiles, plates, pipes and metal products. For convenience of use and distinction, they can also be divided into light rail, large section steel, medium section steel, small section steel, steel cold-formed section steel, high-quality section steel, wire rod, medium-thick steel plate, thin-walled welded pipe, silicon steel sheet for electrical purposes, strip steel, seamless steel pipe steel, welded steel pipe and metal products. And other varieties.

焊管(guǎn)可以通過不(bú)同的製造工藝(yì)進行區分,例如(rú)軋製方法,一般分為冷軋和熱軋,通過這(zhè)兩種(zhǒng)軋製方法(fǎ)生(shēng)產出的產品叫做冷軋焊管和熱軋焊(hàn)管(guǎn),除此之外其製造工藝還有軋製,鍛造,拉(lā)拔,擠壓等工藝(yì)。

Welded pipes can be distinguished by different manufacturing processes, such as rolling methods, which are generally divided into cold rolling and hot rolling. The products produced by these two rolling methods are called cold-rolled welded pipes and hot-rolled welded pipes. In addition, the manufacturing processes include rolling, forging, drawing and extrusion.

除了上述的區分方法(fǎ)隻在還有就是根據鋼材的(de)含碳量進行區分,含碳量在0.04%-2.3%之間的叫做鐵碳合金,為了保證方管的塑性和強度一般含碳量不超過1.7%,1.5%為最佳含碳量,除此之外鋼材中也可以加入鐵,碳,矽,錳等(děng)元素(sù)。除了(le)上麵我們介紹的,還具有很(hěn)多的區分方法(fǎ),這裏我們就不做詳細的介紹了。

In addition to the above-mentioned method of distinguishing only according to the carbon content of steel, the carbon content is between 0.04% and 2.3% called iron-carbon alloy. In order to ensure the plasticity and strength of square tubes, the carbon content is generally less than 1.7% and 1.5% is the best carbon content. In addition, iron, carbon, silicon, manganese and other elements can also be added to steel. In addition to the above, there are many ways to distinguish between them. Here we will not give a detailed introduction.